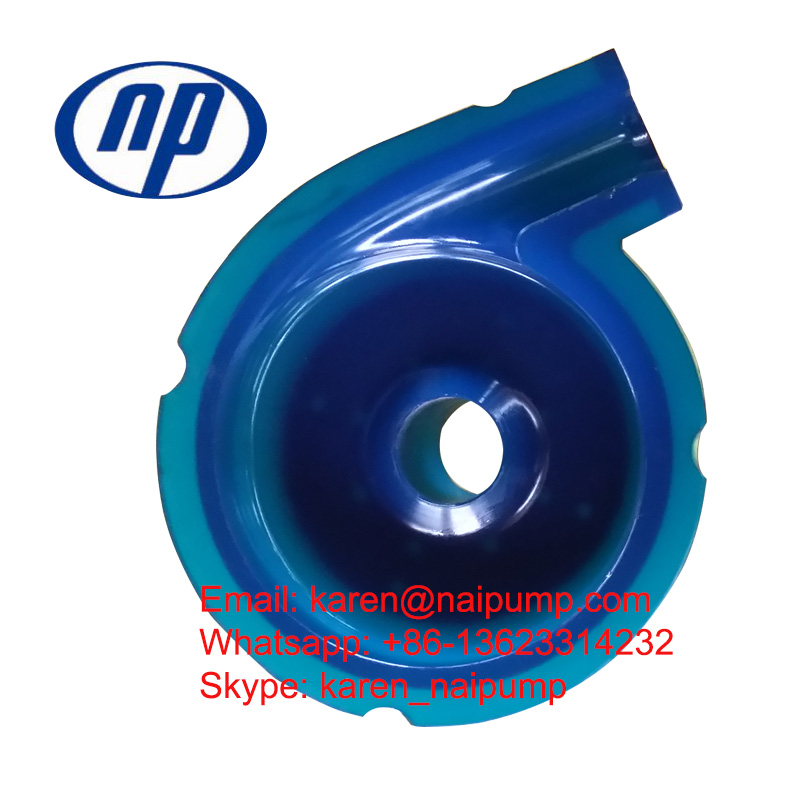

Bagian Pengecoran Uretan untuk pompa

Poliuretan (juga bernama PU) adalah bahan n unik yang ha s elastisitas karet dikombinasikan dengan ketangguhan dan daya tahan logam. Ini memungkinkan insinyur untuk mengganti karet, plastik, dan logam dengan ketahanan abrasi dan sifat fisik terbaik. Polyurethane dapat mengurangi pemeliharaan tanaman.

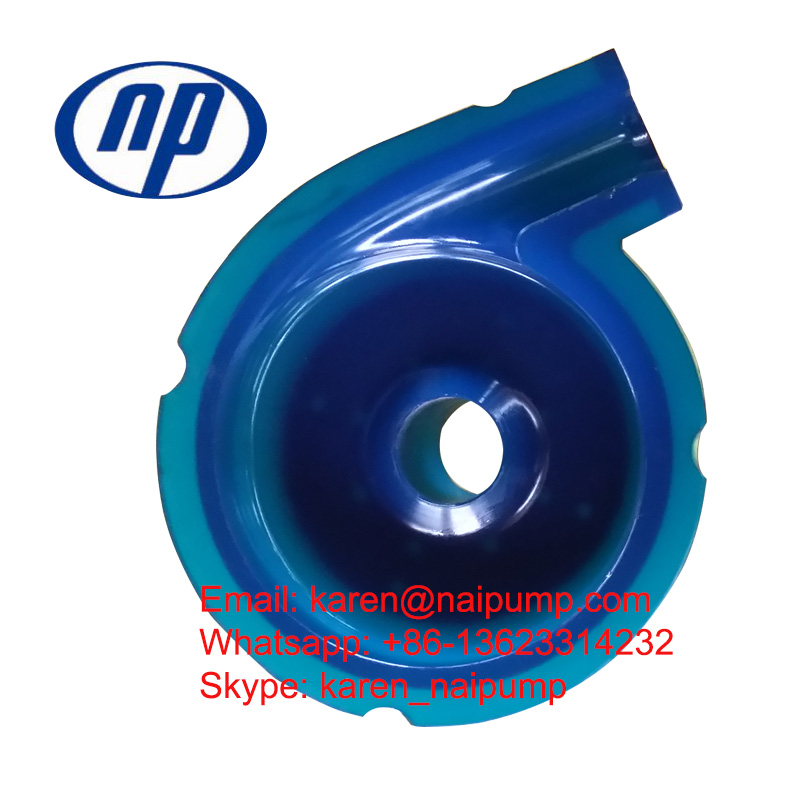

Impeller pompa lumpur poliuretan (PUR dan PU) dibuat oleh Poliuretan yang merupakan polimer yang terdiri dari rantai unit organik yang disatukan oleh tautan uretana. Impeller ini memiliki kinerja yang lebih baik daripada impeller karet alam untuk transportasi bubur.

Selain itu, kami juga memiliki Polyurethane Cover Plate Liner, Frame Plate Liner, Throat Bush, Frame Plate Liner Insert dll.

Materials

|

NBR,Viton/FKM,Siicone/VMQ,EPDM,FFKM,HNBR,PU,CR,FVMQ,PTFE

|

Temperature

|

NBR(-40~120°C),CR(-40~120°C)

Viton(-20~200°C),Silicone (-70~220°C)

EPDM(-50~150°C),PU(-40~90°C)

|

Applied industry:

|

extensively used in chemical industry, petroleum industry, medical

technique, food industry, sewage-disposal industry, steel industry,

semi-conduct industry and so on.

|

Main advantage:

|

1) excellent anti-chemical character. It almost applies to all mediums.

|

|

2) temperature range is very wide.

|

|

3) anti oil function is very good.

|

|

4) long service life.

|

Operation conditions

|

Pressure:<50MPa

|

|

Temperature:-20°C ~ 220°C

|

|

|

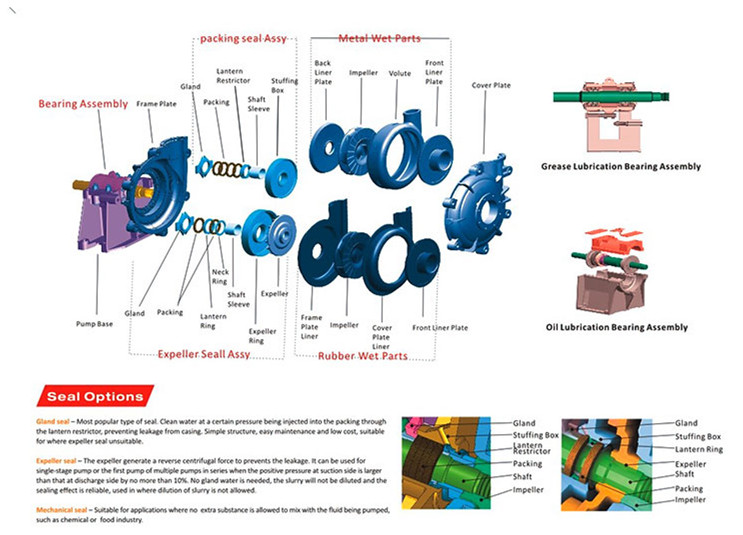

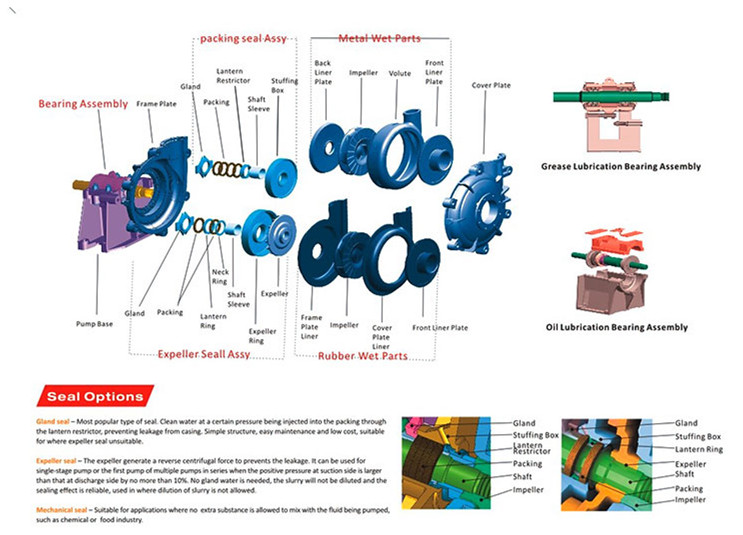

Gambar Konstruksi:

Karakteristik

Ketahanan abrasi dan sobek dari Uretan jauh lebih baik daripada karet, sementara memiliki daya dukung beban yang lebih tinggi. Com p ared untuk plastik, urethanes memiliki ketahanan dampak unggul, sementara memiliki sifat aus yang sangat baik dan memori elastis. Selain itu, PU lebih iklan Ance v dalam pengurangan berat badan, pengurangan kebisingan dan ketahanan aus daripada bagian logam.

Namun, Uretan tidak cocok untuk suhu melebihi 70ºC dan untuk asam dan alkali pekat, keton, ester, hidrokarbon terklorinasi dan nitro.

Ikhtisar Produk:

Suku cadang pompa poliuretan / suku cadang PU / Suku cadang poliuretan / Suku Cadang Pompa Lumpur OEM / Pompa Lumpur OEM / Impeller OEM / Suku Cadang Pompa Paduan Chrome Tinggi OEM

Produk terkait lainnya

|

NAIPU Main Pump Material

|

|

Material

|

Description

|

Application

|

Pump Parts

|

|

A05

|

High Chrome Alloy Cr26

|

neutral ,resistant to alkali but not acid

|

Impeller,Liners

|

|

A49

|

Low Carbon High Chrome Alloy Cr26

|

usually in desulphurization condition

|

Impeller,Liners

|

|

A51(A33)

|

Wear Resistant and Abrasion resistant alloy

|

usually in phosphuric acid,desulphurization and Sulfuric acid working conditions

|

Impeller,Liners

|

|

C21

|

Martensitic Stainless Steel

|

|

Shaft Sleeve,Locating Sleeve

|

|

C23

|

Austensitic Stainless Steel

|

|

Lantern Ring,Lantern Restrictor,Packing Gasket

|

|

D21

|

Ductile Iron

|

|

Cover Plate,Frame Plate,Bearing Housing ,Frame

|

|

D81

|

Galvanized Ductile Iron

|

|

Packing Gland

|

|

E02

|

20# Steel

|

|

|

|

E62

|

20# Galvanised Steel

|

|

|

|

E05

|

45# Steel

|

|

Shaft ,Shaft Key

|

|

E65

|

45# Steel

|

|

|

|

G01

|

HT200

|

|

|

|

G61

|

Gray Iron

|

Base ,Bearing Housing,Frame Plate/Cover Plate,Grease Retainer,Lower Strainer

|

Labyrinth Ring,End Cover

|

|

J04

|

C21 Alumina Plating

|

|

Usually white color ,Shaft Sleeve

|

|

J05

|

C21 Chromic Oxide Plating

|

|

Usually black color,Shaft sleeve

|

|

Q21

|

Aramid fiber ,yellow

|

|

Packing

|

|

R08

|

Natural Rubber

|

|

impeler

|

|

R26

|

|

|

impeller

|

|

R33

|

Natural Rubber

|

|

cyclone liners,pump liners,impeller etc.

|

|

R38

|

Natural Rubber

|

|

impeller

|

|

R55

|

Natural Rubber

|

|

impellers,liners

|

|

S01

|

EPDM

|

Acid Resistant but not wear resisting,high temperature

|

Discharge Gasket,Intake Gasket,Volute Liner Seal ,also for wet end parts

|

|

S10

|

Nitrile Butadiene Rubber

|

|

O Rings

|

|

S12

|

|

|

impeller, liners

|

|

S31

|

Hypalon

|

|

|

|

S21

|

Butyl Rubber

|

high temperature resistant and antioxidant

|

impellers,liners

|

|

S42

|

Neoprene Rubber

|

High Temperature resistant ,weather resistance,ozone resistance,Grease Resistance

|

impeller,Liners

|

|

U01

|

Polyurethane

|

Tension Resistance,High Tensile strength

|

impeller,Liners

|

|

S44

|

Neoprene Rubber

|

|

|

|

S50

|

Fluororubber

|

High Temperature and acid resistant,

|

Gasket ,wet end parts

|

|

Y08

|

Ceramic

|

|

|

|

J31

|

|

|

Shaft Sleeve

|

|

J26

|

Ceramic coated stainless steel

|

J26 consists of Y03 Ceramic Coating deposited onto a C26 substrate using a special spray technique.The coating is very hard and offers excellent abrasive wear resistance.The spray technique gives a coating with minimal porosity and excellent interlayer bond strength.J26 is expansion and will not spall.

|

|

|

Basic Part No.

|

Material Code

|

Part Name

|

|

001

|

E62

|

Adjusting Screw

|

|

003

|

G01

|

Base

|

|

005

|

|

Bearing Assembly

|

|

011

|

E62

|

Clamp Washer

|

|

013

|

D20

|

Cover Plate

|

|

015

|

E62

|

Cover Plate Bolt

|

|

017

|

R26A

|

Cover Plate Liner

|

|

018

|

R26A

|

Cover Plate Liner (Half)

|

|

024

|

E62

|

End Cover

|

|

028

|

G01

|

Expeller

|

|

029

|

G01

|

Expeller Ring

|

|

029R

|

R08A

|

Expeller Ring (Rubber)

|

|

032

|

D20

|

Frame Plate

|

|

034

|

E62

|

Frame Plate Bolt

|

|

036

|

R26A

|

Frame Plate Liner

|

|

039

|

E63

|

Frame Plate Stud

|

|

041

|

A05A,R26A

|

Frame Plate Liner Insert

|

|

043

|

R26A

|

Frame Plate Liner (Half)

|

|

044

|

K24

|

Gland Assembly

|

|

060

|

R08A

|

Intake Joint

|

|

062

|

D70

|

Labyrinth

|

|

063

|

K31

|

Lantern Ring

|

|

064

|

S18

|

Impeller O-Ring

|

|

067

|

E62

|

Neck Ring

|

|

070

|

E05

|

Shaft Key

|

|

073

|

E05

|

Shaft

|

|

075

|

D20

|

Shaft Sleeve

|

|

076

|

D20

|

Shaft Sleeve (Long)

|

|

078

|

G01

|

Stuffing Box

|

|

081

|

E02

|

Keeper Plate

|

|

083

|

A05A,R26A

|

Throat Bush

|

|

085

|

E02

|

Cotter

|

|

090

|

S10

|

Lip Seal

|

|

109

|

S18

|

Shaft O-Ring

|

|

110

|

A05A

|

Volute Liner

|

|

111

|

Q05

|

Packing

|

|

117

|

E62

|

Shaft Spacer

|

|

118

|

K31

|

Lantern Restrictor

|

|

118-1

|

K24

|

Lantern Restrictor(Low Flow)

|

|

122

|

R11A

|

Expeller Ring/Stuffing Box Seal

|

|

124

|

R08A

|

Volute Liner Seal

|

|

125

|

R08A

|

Volute Frame Seal

|

|

132

|

R08A

|

Discharge Joint Ring

|

|

138

|

E62

|

Grease Cup Adaptor

|

|

179

|

C23

|

Shaft Sleeve Spacer

|

|

210

|

S46

|

Shaft O-Ring

|

|

217

|

S18

|

Impeller O-Ring

|

|

239

|

C23

|

Impeller Release Collar

|

|

241

|

K24

|

Lip Seal Gland

|

|

302

|

E02

|

Lifting Tube

|

|

303

|

E02

|

Locating Nut

|

|

304

|

E02

|

Volute Lifting Beam

|

|

306

|

E02

|

Shaft Wrench

|

|

310

|

E02

|

Stuffing Box / Expeller Ring

|

|

425

|

R08A

|

Dyna Seal

|

|

430

|

U14

|

Nut Covers

|

|

005

|

|

Bearing Assembly

|

|

019

|

E02

|

Mounting Plate

|

|

041

|

A05A

|

Back Liner

|

|

064

|

S18

|

Impeller O-Ring

|

|

070

|

E05

|

Shaft Key

|

|

092

|

A05A

|

Casing

|

|

102

|

E02

|

Column

|

|

116-1

|

R10A

|

Strainer - Upper (Rubber)

|

|

116-2

|

G01

|

Strainer-Upper (Cast Iron)

|

|

116-3

|

U02A

|

Strainer-Upper(Urethane)

|

|

116-4

|

C23

|

Strainer-Upper(SS Mesh)

|

|

116L

|

U01A

|

Strainer-Lower

|

|

125

|

R08A

|

Back Liner Seal

|

|

154

|

E02

|

Discharge Pipe

|

|

204

|

R00

|

Discharge Pipe Gasket

|

|

231

|

E02

|

Suction Pipe

|

|

290

|

E02

|

Spacer

|

|

293

|

E02

|

Discharge Pipe Support

|

|

306

|

E02

|

Shaft Wrench

|

|

430

|

U04A

|

Nut Covers

|

|

005

|

|

Bearing Assembly

|

|

019

|

|

Mounting Plate

|

|

041

|

|

Back Liner

|

|

064

|

|

Impeller O Ring

|

|

070

|

|

Shaft Key

|

|

092

|

|

Casing

|

|

102

|

|

Column

|

|

116

|

|

Strainer-Upper

|

|

116L

|

|

Strainer-Lower

|

|

153

|

|

Column Clamp

|

|

154

|

|

Discharge Pipe

|

|

290

|

|

Spacer

|

|

291

|

|

Socket Head Protectors

|

|

293

|

|

Discharge Pipe Support

|

|

306

|

|

Shaft Wrench

|

|

421

|

|

U-Bolt

|

Material Code

|

Applications

|

Remarks

|

G01

|

Casing,Frame,Bearing Housing,Stuffing Box,Stuffing Gland

|

Grey Iron

|

D21

|

Casing,Frame,Bearing Housing

|

Spheroidal Graphite Cast Iron

|

A05/A33

|

Impeller,Volute,Expeller,Throat Bush,FPL,Expeller Ring

|

High Chrome Alloy

|

A49

|

Impeller,Volute,Throat bush,FPL

|

|

R26/R33/R55

|

Impeller,Volute,Throat bush,FPL

|

Rubber

|

OEM Material

|

Special material for pumps and pump parts are available according to clients chemical component request.

|

|

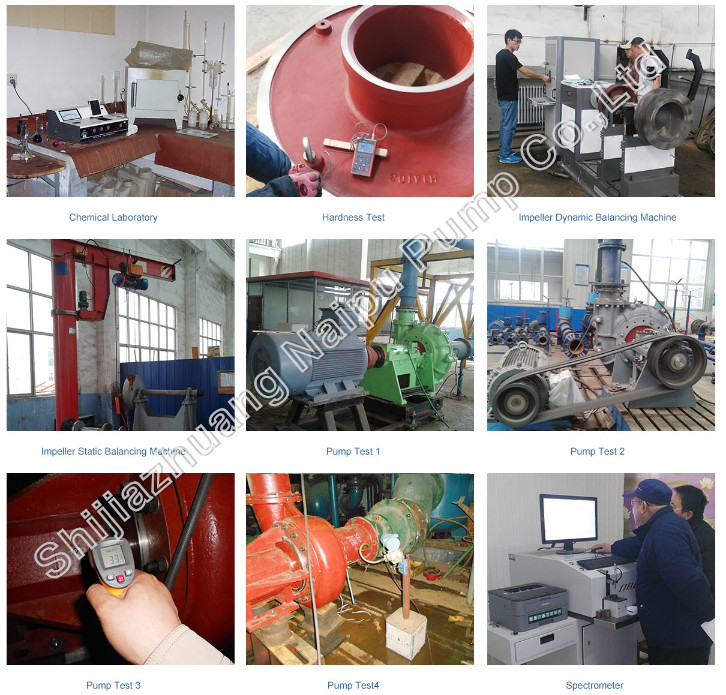

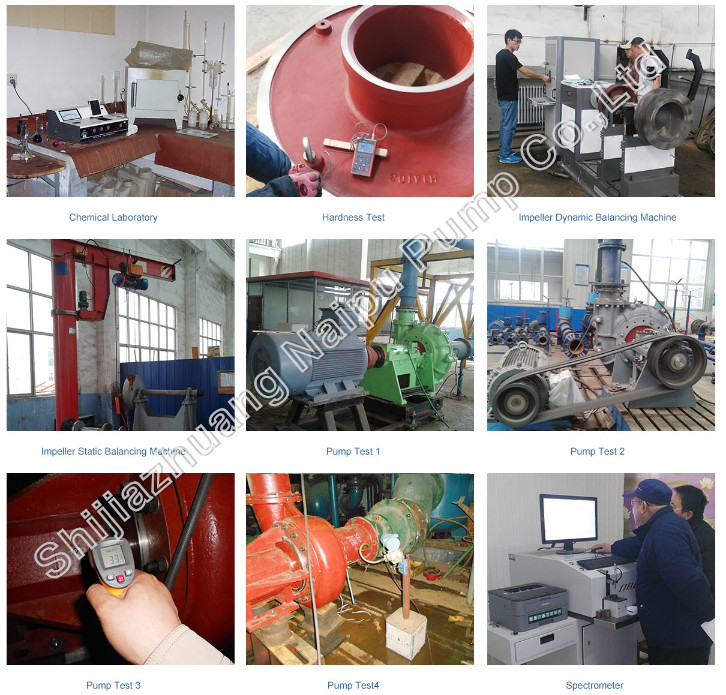

Sistem Kontrol Kualitas:

Kami menetapkan berbagai titik pemeriksaan di seluruh lini produksi, yang di seluruh Bahan Baku, Bahan Pengisian, Pemeriksaan Permukaan dan Perlakuan Panas, Analisis Bahan, Pengujian Cadangan, dan Pengujian Pompa, dll.

Kami menetapkan sistem QA dan QC yang ketat, kami dapat menyediakan catatan kontrol kualitas seperti "Deteksi Spektrum" "Inspeksi Mikroskop Metalografi" "Uji Blok" Deteksi Cacat Ultrasonik" "Pengujian Penetrasi" dll. Dan laporan pengujian terkait kepada klien kami jika perlu , seperti "Laporan Uji Material" "Laporan Uji Dimensi" "Laporan Uji Balancing Rotor" "Laporan Uji NDT" "Laporan Inspeksi Kekerasan" dll.

Detail Kontak:

Shijiazhuang Naipu Pump Co., Ltd

Tambahkan: No.368 Xinshi North Road, Zona Pengembangan Industri Teknologi Tinggi Shijiazhuang, Hebei, Cina 050091.

Skype: karen_napump

Kontak Person: Karen Tan

Jika Anda memiliki pertanyaan, jangan ragu untuk menghubungi kami.